Revolutionizing Industrial IoT

“iLens solution as a comprehensive IoT solution has helped us to simplify connectivity to machines, perform data acquisition, monitor and archive Plant Control room data for analysis.”

Mr. Gopi Krishan M, Deputy General Manager-IT,

Orient Cement Limited, Hyderabad, India

Solution

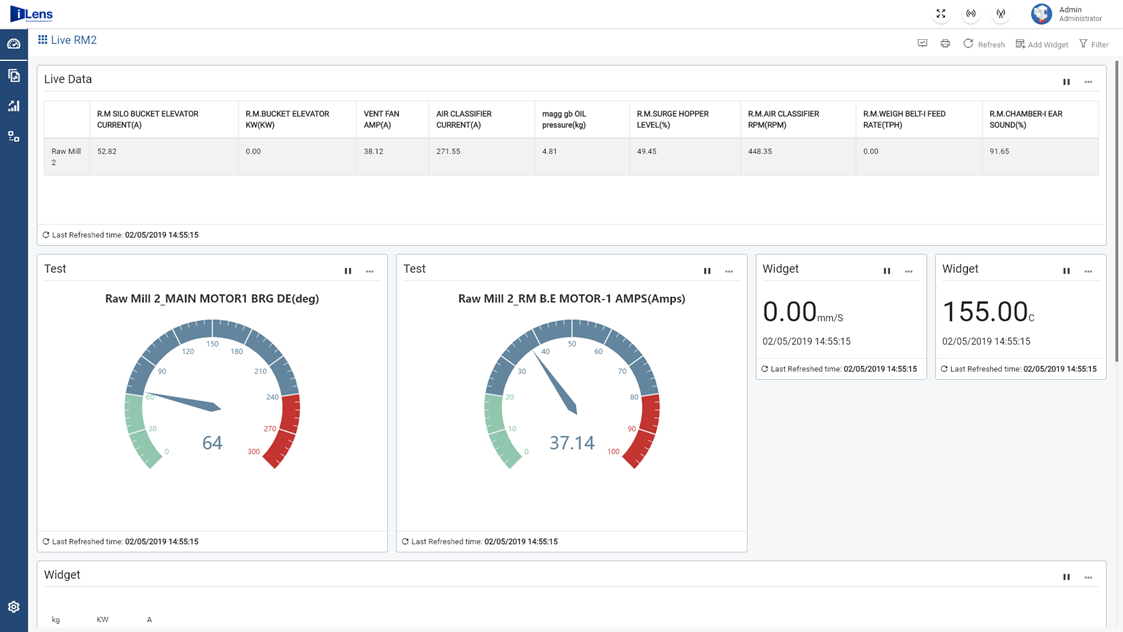

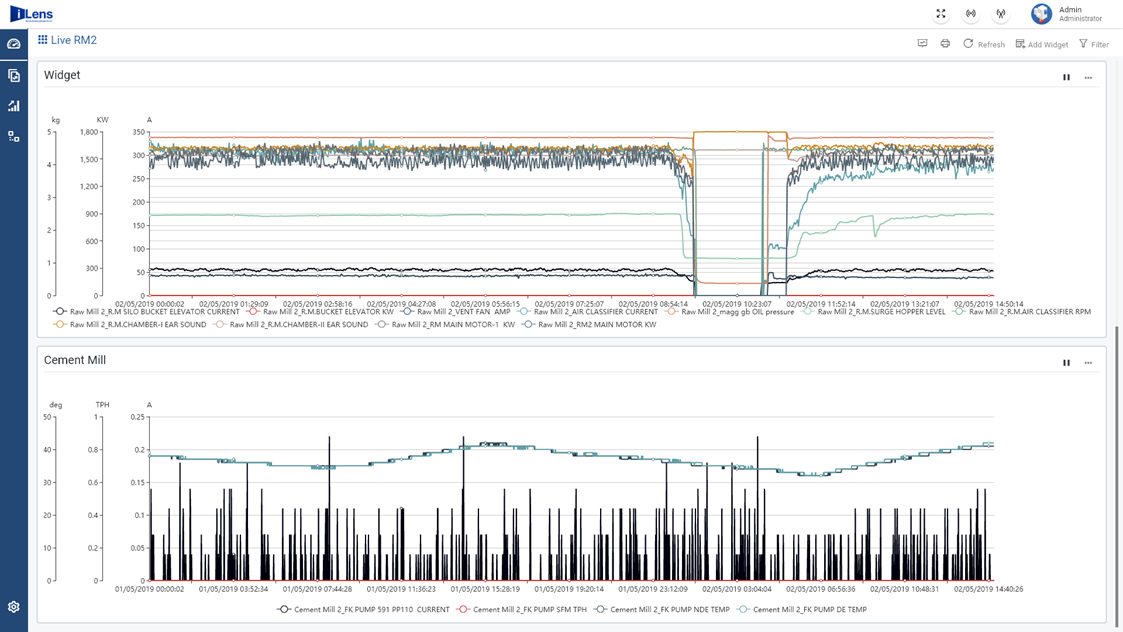

Knowledge Lens as a “Valued Partner in Progress” implemented iLens – Industrial IoT Solution at Orient Cement Limited, Devapur. We interfaced the Plant’s PLCs (Programmable Logic Controller) with in-built protocol support to perform real-time data acquisition of around 4000 parameters across 3 units totaling 9 PLCs to monitor the plant data, storage of historian data and provide dashboards.

The data was stored in a highly scalable big data platform which served as a unified storage repository, to perform monitoring and analytics.

Our solution iLens facilitated the storage of large amounts of data for a longer period of time, and a mechanism to back up and synchronize the data from Plant network to Corporate network in a secure manner.

Technology

Big Data, Ethernet IP, Modbus, MQTT

Benefits

- Centralized real-time platform for operators to monitor accurate voltage, current, rpm, temperature, weight etc, for consumption and possible forecasting.

- Smart Integration with PLCs with Plug and Play protocol support for data fetch.

- High scalability in-memory platform to crunch ingested data.

- Digital Dashboard with Live Monitoring at various levels (for example, Operations Head, Production offices etc.)